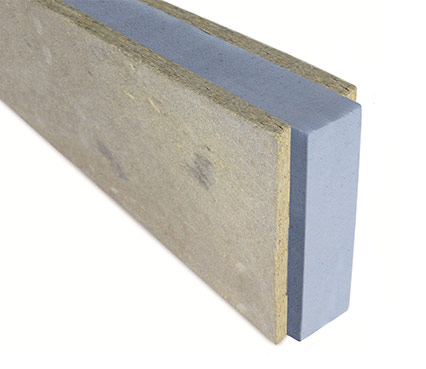

The BetonSilent panel is an element of completion of the light walls with thermo-acoustic insulation inside. It looks like a sandwich panel consisting of two BetonWood type cement bonded particle boards 20 mm thick, between which a 50.5 mm thick extruded polystyrene XPS panel is inserted. The length of the septum is 1200 mm, while the height can vary from 100 to 300 mm.

The rigid insulation panel BetonSilent is therefore made up of three coupled layers in the factory: two high density BetonWood cement bonded particle boards (1350 kg/m³) and very high compressive strength (9000.00 kPa) made of Portland type cement conglomerate and debarked pine wood fiber, and a central layer consisting of an extruded polystyrene panel.

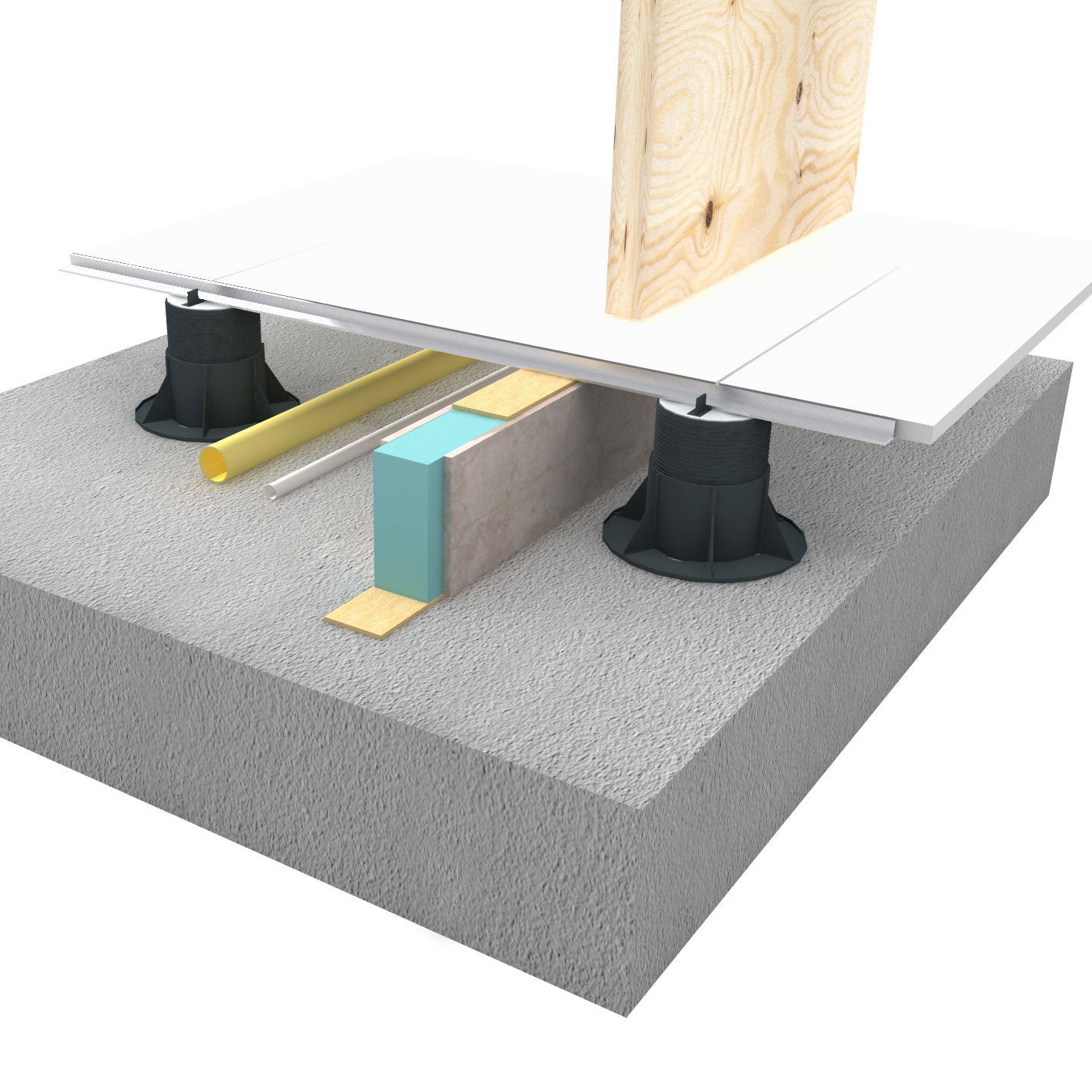

BetonSilent is a vertical element for filling the plenum of false ceilings and elevated floors, essential in order not to compromise the acoustic performance of the partition. In case of use under the raised floor, the partition can be laid without the need for fixing, to allow easy removal in case of maintenance. In case of use above the false ceiling, it is instead necessary to mechanically fasten it to the soffit of the floor.For further thermal and acoustic insulation it is recommended to lay above and below the sandwich, therefore in the surfaces in contact with the intrados of the floor and the paneling of the floating floor, of a strip of natural insulating material Fibertherm Soundstrip in flexible pressed wood fiber. It can be easily seen from the image and the stratigraphy in the data sheet.

BetonSilent is used as:

• thermal and acoustic insulation of traditional and elevated floors;

• correction of thermal bridges;

• thermal and acoustic insulation of false ceilings;

• insulated systems for windows and doors;

• dry screeds.

If you are interested in this type of solution, we recommend that you take a look at our other coupled products in the section Coupled panels.

The BetonWood cement bonded particle board is also made exclusively with wood from controlled forests in compliance with the FSC directives (Forest Stewardship Declaration).

The cement bonded particle board has so many advantages, including:

• very high compression resistance;

• high resistance to climate change and frost;

• insects and fungi are unable to attack or damage it;

• thanks to its physical and mechanical characteristics, the product is considered one of the best materials for light weight constructions;

• incombustible (A2 according to the DIN 4102 Standard);

• free of formaldehyde and free of asbestos, asbestos etc .;

• free of recycled inks (present in materials with recycled cellulose);

• resistant to atmospheric agents;

• workable with wooden tools;

• high flow rate;

• recyclable, ecological, respects the environment;

• construction material tested and authorized according to the European standards in force.

The extruded polystyrene XPS panels are characterized by:

• very effective protection against the summer heat, due to the remarkable intrinsic insulating properties;

• high capacity to absorb ambient humidity, which constitutes a natural hygrometric regulator system;

• quality guarantee, thanks to continuous checks and tests carried out according to the European standards in force.