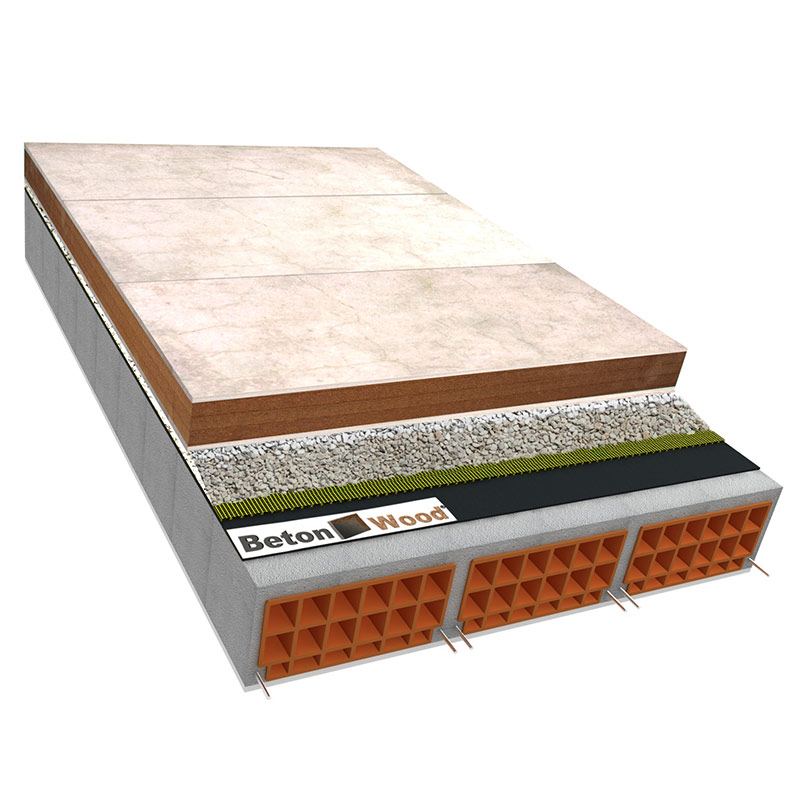

Betonroof base panel is a building material intended for outdoor use due to its high thermal lag due to its 3-level structure; in fact, having several levels in materials with different densities reduces thermal conductivity and therefore lengthens the passage of heat from the outside to the inside, thus creating a comfortable indoor climate of the building.

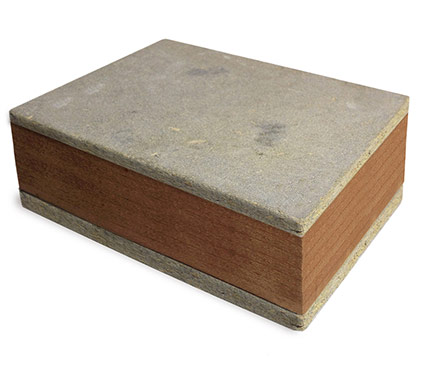

The insulating Betonroof base material is produced throught the coupling of three panels of two different types: two of these are made with BetonWood cement bonded particle boards which have a high density equal to 1350 Kg/m³ and a high compression resistance; among these there is one in wood fiber type Fibertherm Base, highly insulating both from a thermal and acoustic point of view, totally natural and recyclable.

It can easly installed on floors, walls and roofs, it has an excellent versatility, fire resistance certified in A2 class, weather agents resistance, and it can insulate every part of the building:

• it can be used as thermal and acoustic insulation of roofs and floors that require a high mass to increase the thermal lag and noise reduction;

• also ideal for insulating both flat and pitched roofs as the cement bonded particle board surface protects the wood fiber from atmospheric agents, humidity and fire.

• the panel is fully walkable and therefore suitable for laying on horizontal surfaces;

• the panel is characterized by a high compressive strength equal to 9000 kPa and therefore is suitable for use in public places such as schools, hospitals, libraries, offices, but also fire escape routes and so on ..

If you are interested in this type of solution, we recommend that you take a look at our other coupled products in the section Coupled panels.

All materials are also recyclable and certified. The BetonWood cement bonded particle board is also made exclusively with wood from controlled forests in compliance with the FSC directives (Forest Stewardship Declaration).

The cement bonded particle board has so many advantages, including:

• very high compression resistance;

• high resistance to climate change and frost;

• insects and fungi are unable to attack or damage it;

• thanks to its physical and mechanical characteristics, the product is considered one of the best materials for light weight constructions;

• incombustible (A2 according to the DIN 4102 Standard);

• free of formaldehyde and free of asbestos, asbestos etc .;

• free of recycled inks (present in materials with recycled cellulose);

• resistant to atmospheric agents;

• workable with wooden tools;

• high flow rate;

• recyclable, ecological, respects the environment;

• construction material tested and authorized according to the European standards in force.

The wood fiber FiberTherm base panels are characterized by:

• a high compression resistance;

• an excellent compression resistance;

• very effective protection against the summer heat, due to the remarkable intrinsic insulating properties;

• opening to the diffusion of water vapor, which contributes to the construction of breathable buildings with high comfort;

• high capacity to absorb ambient humidity, which constitutes a natural hygrometric regulator system;

• quality guarantee, thanks to continuous checks and tests carried out according to the European standards in force.